LAYERS WITHOUT LIMITS

PREMIUM QUALITY COATINGS

Ferro Arte de Mexico, S.A. de C.V., Powder Coating Division is a coating company that offers Powder Coatings (15) powder coating services to the metal mechanical industry which has been a premier powder coating supplier with a strong commitment to people, products, and service

The divisions primary focus is on powder coating, wet paint, sandblasting and shot blasting applied to fabricated steel parts for various manufacturing companies.The Company’s motto is “Fast and Flexible Service”. Our objective is to provide our clients powder coating of their metal components on time. Customers can rely onPowder Coatings (2) Ferro Arte de Mexico for fast proposals, and on time delivery of their powder coatings. Meeting turnaround times is our top priority to produce long-term relationships.

SCRATCH AND WEATHER RESISTANT

SUPER DURABLE POWDER COATINGS

PROPRIETARY TECHNOLOGY

Our coatings provide durability, scratch resistance, and weather resistance. We have a wide range of colors, glosses, finishes and textures. Whether you are dealing in steel, aluminum, or galvanized steel. our process will give you the long lasting, quality finish you need.

Powder coating is an environmentally friendlier option than painting with limited Volatile Organic Compound emissions, and less hazardous waste.

Powder coating is an environmentally friendlier option than painting with limited Volatile Organic Compound emissions, and less hazardous waste.

Our expert finishing technicians apply superior powder coat finishes that are proven to be extremely durable for metal products such as outdoor furniture, automotive parts, railings, and just about anything else that is metal.

Our Process

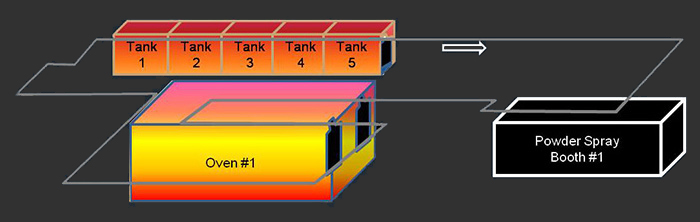

Ferro Arte utilizes a 356 foot powder coating line #1 with a 36’L x 10´W x 5´H oven located in one of the company’s 15,000 sq. foot areas which provides the facilities to wash, phosphate, dry, powder, bake or paint , inspect and pack parts for shipping all under roof. Powder Coatings.

WASH SYSTEM

- Tank #1 - Degreasing

- Tank #2 - Rinse

- Tank #3 - Rinse

- Tank #4 - Phosphate

- Tank #5 - Seal

OVEN GAS

- Powder Coating Baked

- 36'L X 10'W X 5'H

- Speed - 3Ft Per Minute

- Oven Cycle Time - 20 Minutes

- Oven Temperature - 365/410 Degrees

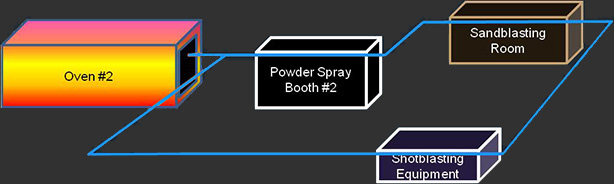

Ferro Arte also utilizes a second 140 foot powder coating line with a 20’L x 8´W x 8’H oven. In this 3.300 sq. foot area, the line provides shot-blast equipment room capacity of 69” diameter x 18”h, and a sandblasting room measuring 4´W x 16´L x 8´H, and can also paint or powder coat, bake, inspect and pack parts for shipment without being exposed to the elements.

Quality Control Tests

- Paint Cured Rest: MEK

- Hatch Testing

- Thickness Gauge

- Glossmeter

- Powder Spray Booth

Powder Spray Booth Equipment

Chemicals Used Provided By